PRODUCTS

Innozinc

PRODUCTS

Innozinc

SMART ULTRAFINE MIST SPRAYER

Public Health System

-

Spraying ultrafine particles at room temperature

Spraying ultrafine particles at room temperatureSprayed in the form of ultra-fine particles that are smaller than air at room temperature without changing the fragility (4.3 ㎛ ~ 11 ㎛)

If the particle size decreases to 1/10, the number of particles increases by 1000 times, and the surface area per volume increases by 100 times.

-

Use of less chemical / maximize pesticide sterilization

Use of less chemical / maximize pesticide sterilizationHigh control effect with 40 ~ 60% of chemical

The smaller the particle size,the faster the air dilution and photolysis by sunlight.

Time for the particle to fall 1 m 10 ㎛ / 20 minutes -

Almost no residual drug

Almost no residual drugNo damage to electronic equipment and interior documents (no stains and corrosion)

The smaller the particle size, the greater the number of particles and surface area, which can increase the contact frequency.

-

Minimize environmental pollutants

Minimize environmental pollutantsNo soil / water pollution

Minimizing air pollution

˙High Effect: 95~100%

˙Saving Labor Cost: Upto 90%

˙Very Less Chemical Remaining: 1/22 (Standard 3ppm) Eco friendly

˙Chemical & Water Saving: Upto 60% Saving operational cost

Product Features_Details

| Configuration | Characteristic | Content |

|---|---|---|

| Vaporize at room temperature | Low temperature boiling | ˙There is no weakening of drug or Chemical - It is not a vaporization method due to heat, so there is no change in fragility. |

| Non-combustion method | ˙No oxidation pollutants and dioxin - SO2 participates in the breathing physiology of plants and breaks chlorophyll by penetrating into the pores and drainage holes of the leaves. |

|

| Ultrafine particle injection | Particles lighter than air (4.3 ㎛~11 ㎛) |

ㆍChemical saving (40~60%) - When the particle size decreases to 1/10, the number of particles increases by 1000 times and the surface area increases by 100 times. - Because it floats in the air for a long time (diffusion / permeability), it can control pests and harmful bacteria. |

| Very little chemical residue |

ㆍNo food residues and plant damage (minimization) ㆍNo damage to electrical / electronic equipment and interior, documents, copy (cloth), and other objects - Conventional combustion (heating) method generates oxides, especially SO2 and SO3 corrode electronic products and metallic products. |

|

|

ㆍNo soil or water pollution - Minimizing air pollution |

||

| Reference |

ㆍSmoke machines (heated fumes) generate oxidizing pollutants and highly toxic dioxins - Smokers (combustion temperature 400-600) particles are 2-40, smokers (heating temperature 200-700) is about 2-6. |

|

K-SPACE MASTER performance comparison

| Spray equipment performance comparison |

K-SPACE MASTER | Ultrafine atomizer(ULV) | Smoke / smoke | |

|---|---|---|---|---|

| Technology | Spray method | Ultrafine atomization | Ultrafine spray | Heating (combustion) method |

| Particle size | 4.3 ㎛~11 ㎛ | Aerosol 20 ㎛ | Oxidizing gas (0.1~40 ㎛) | |

| Diffusivity & permeability | Light like air | Heavier than air | Heavier than air | |

| Eco-Friendly | Residual | X | Big | small |

| Vandalism | X | Slight damage | Slight damage | |

| Effectiveness | Space sterilization power | 99% sterilization | Normal | Almost none |

| Insecticidal | Excellent (integrated Control) | Normal | Low (less than 20%) | |

| Time | Fast Control (1~2hrs) | 4~12 hrs | ||

| Remark | Oxidative pollutants | |||

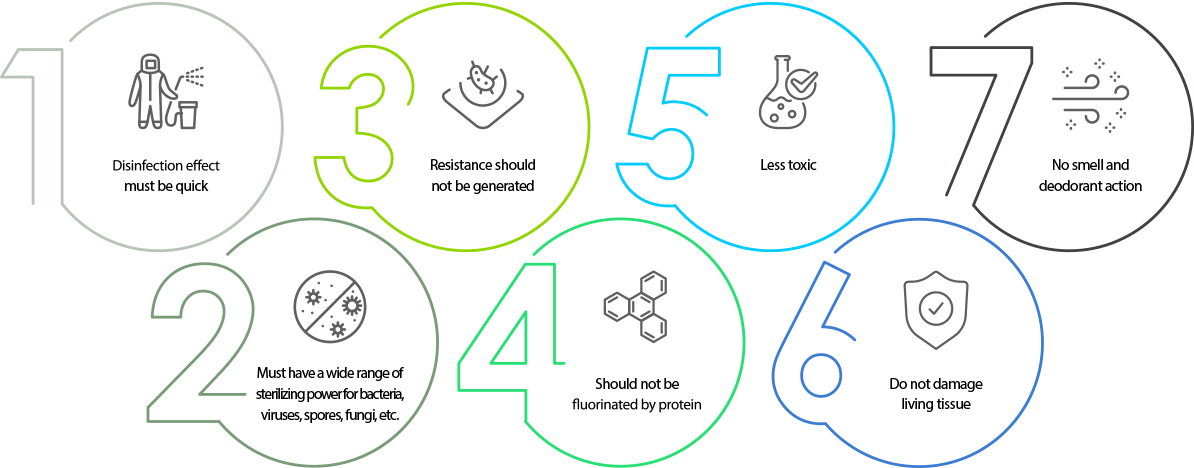

Action and conditions of field control & quarantine

| 1. Disinfection | How to kill pathogens but survive nonpathogenicity (chemicals, pasteurization, etc.) |

|---|---|

| 2. Sterilization | Pathogenicity, non-pathogenicity, and spore killing all microorganisms (flame, dry heat, high pressure steam, filtration, chemical sterilization, etc.) |

| 1. Physical disinfection | Heat (incineration, wet heat, dry heat), flame, ultraviolet light, radiation |

|---|---|

| 2. Chemical disinfection | Disinfectant |

| 3. Physical and chemical disinfection | Disinfectant and heat mixing |

| 1. density | Disinfectant is not necessarily effective because it has a high concentration, but the effect may be different depending on the type of disinfectant and the object to be applied. |

|---|---|

| 2. Temperature | In general, the sterilizing power is doubled when the temperature increases by 10 degrees, but chlorine, etc., decreases when the sterilizing power increases. |

| 3. PH | Effective for basic, neutral and acidic |

| 4. Organic matter | When organic substances such as blood are present, the sterilizing power decreases. |

| 5. Antagonism | Combination of anionic and cationic properties reduces sterilization power |

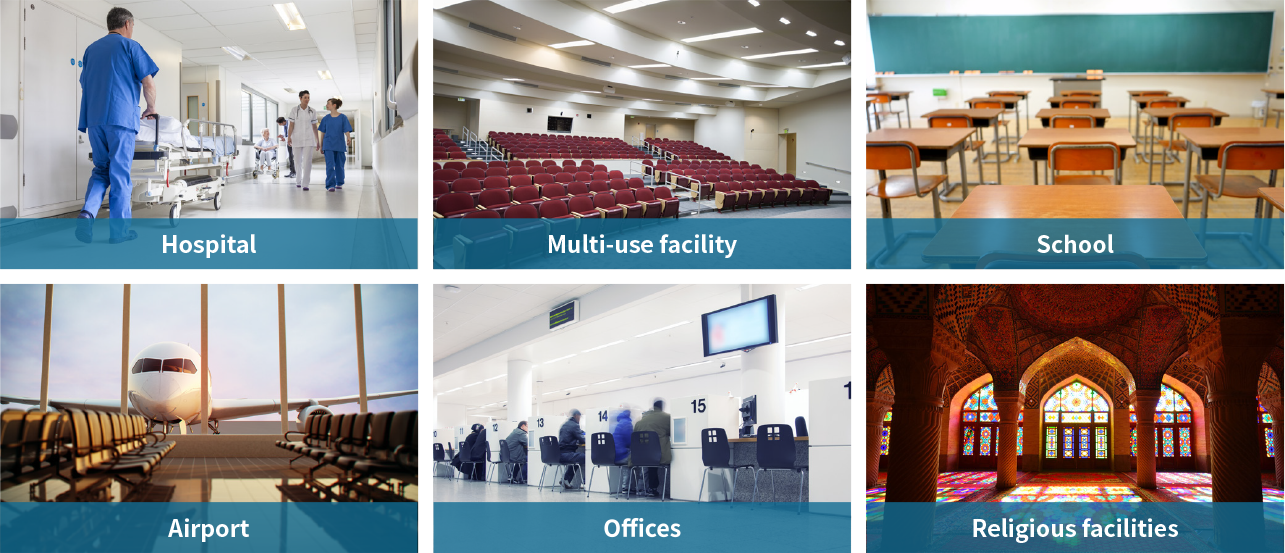

Spatial Quarantine Application Case

Government offices, auditoriums, conference rooms, hospitals, military units, ships, prisons, train stations, schools, wastewater treatment plants, multi-use facilities, indoor markets, warehouses, food processing facilities, large restaurants, etc.

Product line (General buildings, etc.)

| KSM-4 | KSM-5 | |

|---|---|---|

| Product Image |  |

|

| Size(mm) | 480*450*720 | 1000*400*900 |

| weight | 40Kg | 45Kg |

| Covering Space | ~1200㎥ | ~2000㎥ |

| Air compressor | Separated Potable 3.5 Hp | Separated Potable 5 Hp |

| Sprayed Capacity | 4L/hr | 5L/hr |

| Micro Particle Size | 8 ㎛~11 ㎛ | 8 ㎛~11 ㎛ |

Field application examples of agricultural and livestock control systems

Greenhouse and vinyl house, flower-linked house, barn,mushroom house, indoor zoo and botanical garden, nursery plant

Product line (Agriculture, Livestock)

| A-4 | A-5 | A-10 | A-15 | |

|---|---|---|---|---|

| Product Image |  |

|

|

|

| Size(mm) | 1000*400*900 | 1000*400*900 | 1000*400*1200 | 1000*400*1500 |

| weight | 40Kg | 45Kg | 65Kg | 70Kg |

| Covering Space | ~1200㎥ | ~2000㎥ | ~13,000㎥ | ~20,000㎥ |

| Air compressor | Separated Potable 3.5 Hp | Separated Potable 5 Hp | Separated Potable 10 Hp | Separated Potable 15 Hp |

| Sprayed Capacity | 4L/hr | 5L/hr | 10L/hr | 15L/hr |

| Micro Particle Size | 8 ㎛~11 ㎛ | 8 ㎛~11 ㎛ | 4.3 ㎛~11 ㎛ | 4.3 ㎛~11 ㎛ |